What are dimensional letters (3D Letters)?

Dimensional letters are three dimensional (3D) sign letters, which are made out of metal, acrylic or plastic.

How are 3D sign letters made?

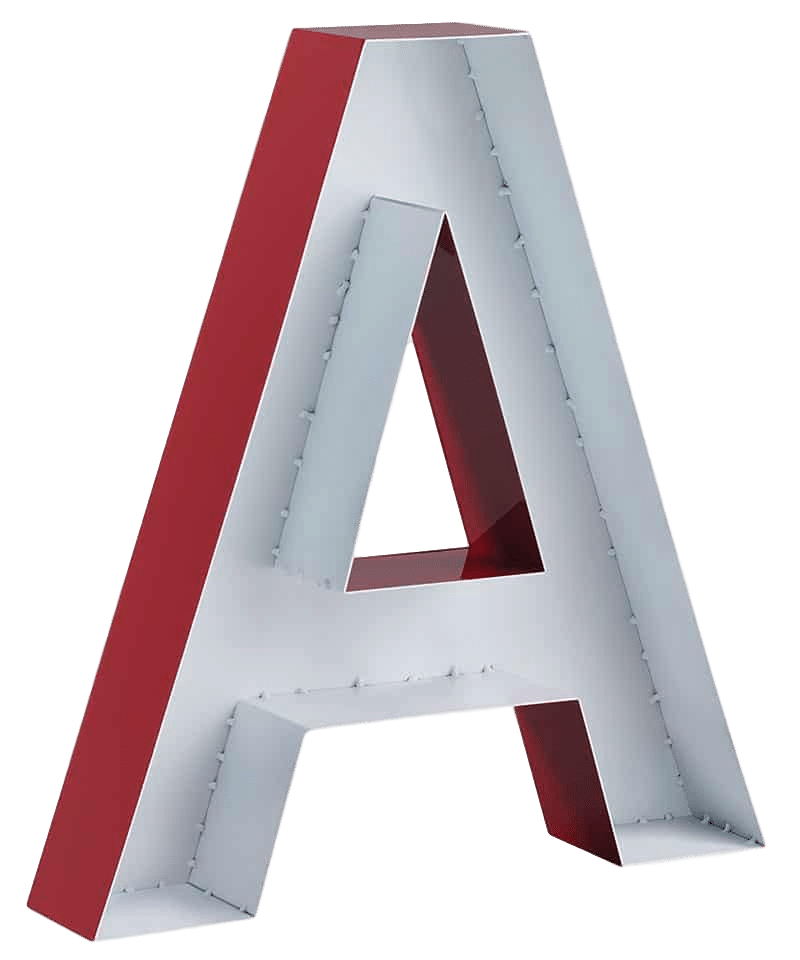

Different materials options have their own unique production process. Fabricated metal letters, for example, are made by bending thin metal returns (sides) around a flat CNC cut metal face. The returns (sides) and face are welded together to form the letter (or logo). The inside of these letters are hollow and the letters, themselves, are light weight.

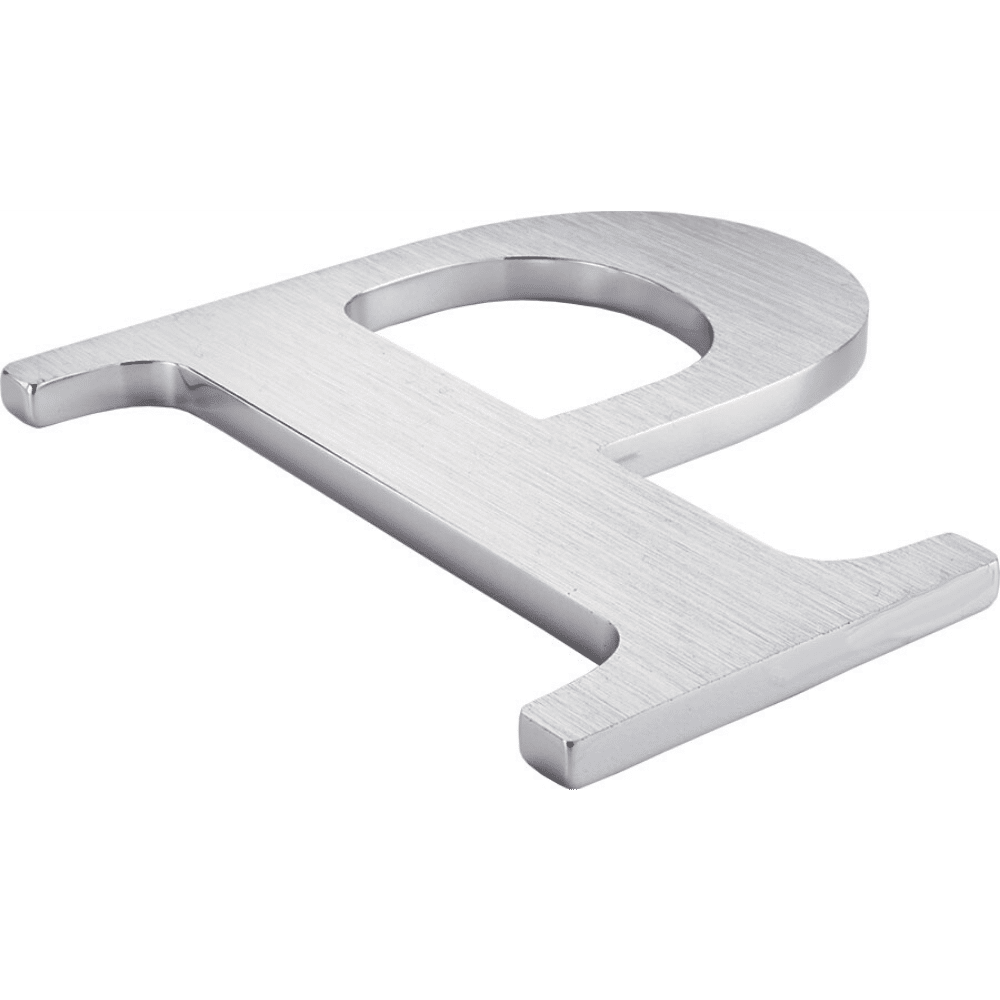

Cut metal letters, also referred to as “Flat cut” letters, are made by machine. A CNC (usually a router or plasma cutter), will cut the letters out of sheet metal. The thickness of the sheet metal determine the thickness of the letters. Cut metal letters are solid and heavier in weight than fabricated metal.

Acrylic letters are made in a similar way as flat cut metal letters, in that a CNC machine (usually a router or a laser), will cut the letters out of a sheet of acrylic. The thickness of the acrylic will be the thickness of the letters. They are solid letters but more lightweight than solid cut metal letters.

What’s the difference between 3D letters and channel letters?

Illumination, my friend. The difference between 3D letters (also called dimensional letters), and channel letters is the presence (or absence) of lighting, To put it simply, channel letters are illuminated, while dimensional letters are not. Click the following link if you’re interested in channel letters.

How are 3D letters mounted?

Letters can be tape mounted or stud mounted. For tape mounted letters, double sided VHB (very high bond) tape is applied to the back of each letter. Stud mounted letters have pre-drilled and tapped holes behind each letter.

Which is better – Stud mounting or tape mounting?

Stud mounting is recommended for heavier letters, such as aluminum letters, steel letters, or really thick acrylic letters. The heavier the letter becomes, the less likely that VHB tape will hold them in place over the long term.

Thinner acrylic letters are easily installed with tape mounting.

Pro tip – Always add a dab of clear silicone being your tape mounted letters. Having two adhesives (the VHB tape and the silicone) offer the best long term results.

I’m a DIY’er. What tools do I need to install?

If the letters are stud mounted, you’ll need a drill, masking tape, a level, silicone, tape measure, and a center punch (optional). If the letters are tape mounted, you can skip the drill and center punch.

Do I need a permit to install my letters?

You most likely will not need a permit if you’re installing indoors, such as an office building or home.

If you’re installing letters on a building, or outdoors, you often will need a sign permit from your local jurisdiction. You should check the permitting requirements in your area.

How soon can I have my sign letters?

Production time will vary based on the material and complexity of the project design. In general, lead times will be:

Cut acrylic or metal (unfinished): 2-4 business days

– With premium metal finish or painting: 7-15 business days

Fabricated metal (unfinished): 3-5 business days

– With premium metal finish or painting: 7-15 business days

How much should I expect to pay?

The price will vary greatly based on material, finish, thickness and complexity of design. On average, for a 12″ high letter in 1/4″ thick aluminum, expect to pay between $100-$200 per letter. The same letter in brass, copper, or stainless steel would add a premium. The same letter in 1/4″ acrylic would be between $40-$100 each.

Can you install my letters for me?

Heck yea! There are few things we enjoy more than installing a nice set of dimensional letters. Yes, really. If you’re located far away from us, don’t worry. We have a national network of professional installers that we’ve developed over 40 years. We can install anywhere in the lower 48.